In the world of industrial processes, heat exchangers are essential devices that help move heat from one substance to another efficiently. One common type is the shell and tube heat exchanger.

This article dives into the significance of standard flanges when used as body flanges in these heat exchangers, providing you with a comprehensive understanding of their design, calculations, and real-world applications. Additionally, we will address common questions and concerns to give you a complete picture of their importance in the industrial landscape.

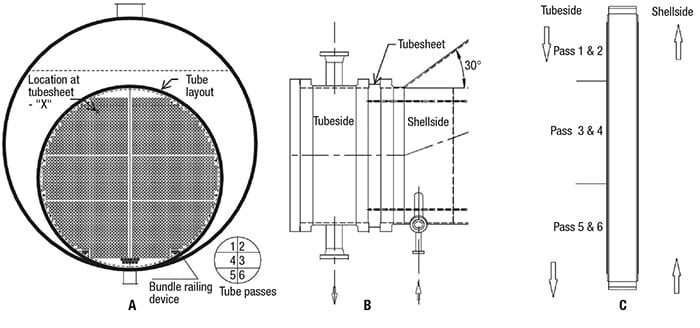

Image Source: Texas Flange

Note: Explore the key applications of body flanges in different industries in our Industrial Applications of Body Flanges guide.

Standard Flanges in Heat Exchangers

In the realm of heat exchangers, flanges are connectors that link different parts of the equipment, including the shell and tube bundle. These flanges, often called “standard flanges,” play a pivotal role in ensuring a secure seal, simplifying maintenance, and managing pressure and temperature differences. Here’s how they fit into the picture.

Design Criteria and Calculations

When body flanges are in use, it simplifies the design process. Unlike custom flanges, standard body flanges come with preset pressure and temperature ratings that conform to industry standards. This means they don’t require complex calculations and design considerations. You can easily find standard flanges designed to fit the dimensions of the heat exchanger’s components.

Choosing the Right Flange

The selection process for standard flanges involves several important factors:

- Flange Material: You choose the material that best suits the operating conditions, considering factors like corrosion resistance, pressure, and temperature.

- Bolting Material: Bolts and nuts must be chosen carefully to ensure the strength and integrity of the flanged connection, matching the application’s demands.

- Gasket Material: The gasket material is selected based on fluid properties, temperature, and pressure.

- Facing Type: Various flange facing types (e.g., Raised Face, Male and Female, Tongue and Groove) are used according to specific application requirements.

- Hub Proportions: The hub proportions of standard flange.

Load Definition:

Flanges must be designed to withstand different loads, such as:

- Gasket Seating Load: This load is applied to ensure proper sealing when the gasket or joint-contact surface is seated. It depends on the gasket material and the effective seating area.

- Operating Condition Load: This load takes into account the hydrostatic end force of the design pressure and maintains sufficient compression on the gasket for a tight joint.

Flanges are pre-defined and are suitable for a broad range of applications.

FAQs – Your Questions Answered

Why are body flanges important in heat exchangers?

Flanges create secure connections and ensure efficient heat transfer in the exchanger.

What’s the difference between standard body flanges and non-standard body flanges?

Standard flanges adhere to established industry norms, while non-standard flanges are custom-made and require more complex design.

How do I choose the right material for flanges?

Consider factors like the operating environment, fluid properties, and temperature and pressure requirements.

Why is the type of gasket material important?

Gasket material affects the tightness of the seal, and the choice depends on the fluids being processed.

What is flange facing, and why does it matter?

Flange facing influences the effectiveness of the seal and ensures even bolt pressure distribution.

Can I use standard body flanges for all heat exchangers?

Standard body flanges are versatile but should be selected based on specific application requirements.

Do standard body flanges help ensure safety in heat exchangers?

Yes, as they come with predefined pressure and temperature ratings, minimizing risks of failure and leaks.

How do I maintain standard flanges in a heat exchanger?

Regular inspection, maintenance, and replacement, if needed, are crucial to ensure continued efficiency.

Are standard flanges compliant with industry standards?

Yes, these flanges are designed to meet recognized industry regulations, such as ASME codes and ANSI standards.

Can standard body flanges reduce operational costs?

Yes, they simplify the design process, making them more cost-effective compared to custom flanges.

What happens if flanges are not properly aligned?

Misalignment can result in uneven bolt pressure, risking leaks or flange deformation.

What is the significance of the load applied to flanges during gasket seating?

This load ensures that the gasket seals correctly, which is vital for preventing leaks.

Can I reuse standard body flanges if I need to replace or upgrade components in my heat exchanger?

Standard flanges are reusable and are designed to facilitate maintenance tasks.

Why are standard flanges a practical choice for design and operations?

The predefined ratings and availability make standard flanges a straightforward and dependable choice.

Can standard flanges handle various types of fluids and temperatures?

Standard Body flanges come in different materials and are selected based on the specific fluid and temperature conditions of the application.

Conclusion

Standard Body flanges are indispensable components in the world of heat exchangers, providing secure connections that ensure efficient heat transfer. While they may not receive accolades, their importance is unquestionable. The use of standard flanges offers reliability, compliance with industry standards, and simplified design, making them a practical choice for seamless integration and cost-effective operations. In the heat exchanger industry, their presence silently contributes to the success of various industrial processes.

If you require more information, Visit: https://www.texasflange.com/