If you’ve ever wondered how pipes, valves, and equipment are connected in various industries, you’ll find them in a crucial component known as “Body Flanges.” In this article, we’ll explore what body flanges are, the different types available, the materials used to make them, and where they are used.

What Are Body Flanges?

Imagine a scenario where you need to connect two pipes securely while ensuring they remain leak-free, even under high pressure and temperature conditions. That’s where body flanges come into play. Body flanges are like strong connectors that join pipes, valves, pumps, and other equipment together to create a network of pipes, allowing fluids to flow smoothly.

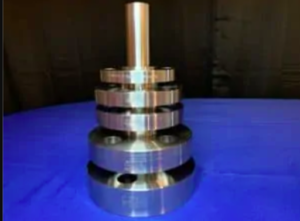

Image source: Texas Flange

Types of Body Flanges

Body flanges come in various types, each designed for specific purposes, Some of them are mentioned below-

1. Weld Neck Flange

Weld Neck Flanges are the most commonly used type. They have a neck extension and a weld bevel, making them ideal for high-pressure applications.

2. Slip On Flange

Slip On Flanges are simpler alternatives to Weld Neck flanges. They accept the pipe into the center/bore and allow welding around the outer diameter of the pipe.

3. Blind Flange

Blind Flanges are designed to cap off a pipe or end a line. They have no bore or inner diameter and can be customized for specific needs.

4. Socket Weld / Counter Bore Flange

Socket Weld or Counter Bore Flanges have a socket for inserting the pipe when space is limited, making them useful in tight spaces.

5. Threaded / Companion Flange

Threaded or Companion Flanges have female NPT threaded centers for connecting to male threaded piping. They are commonly used in reducing connections.

6. Lap Joint Flange

Lap Joint Flanges are intended to fit over a stub end fitting. They have an extended hub and a machined radius at the base of the flat face.

Materials Used in Body Flanges

Body flanges are made from various materials, each chosen based on the application’s requirements:

Stainless Steel

Stainless steel body flanges are used in applications where corrosion resistance is crucial. Grades like 304, 316, and 317 are commonly used.

Duplex & Super Duplex Steel

These are used in demanding environments and are known for their high strength and corrosion resistance.

Alloy Steel

Alloy steel body flanges are suitable for high-temperature applications. Common alloys include F1, F5, F9, and F11.

Carbon Steel

Carbon steel body flanges are versatile and cost-effective. They are often used in industrial settings.

Nickel Alloys

Nickel alloy body flanges, like Inconel and Monel, are used in extreme conditions with high temperatures and pressures.

Copper Alloys

Copper alloy body flanges, such as Cu-Ni 90/10 and Cu-Ni 70/30, are used in specific applications, including seawater environments.

Applications of Body Flanges

Body flanges find applications in various industries, including:

Pharmaceutical Equipment

In pharmaceutical manufacturing, body flanges are used to create reliable connections in piping systems.

Chemical Equipment

Chemical processing often requires body flanges to connect different parts of the system.

Heat Exchangers

Heat exchangers rely on body flanges to maintain secure connections for efficient heat transfer.

Off-Shore Oil Drilling

In the oil and gas industry, body flanges are essential for connecting pipes in offshore drilling operations.

Power Generation

Power plants use body flanges in their piping systems to ensure safe and efficient energy production.

Petrochemicals

In the petrochemical industry, body flanges are used extensively in piping networks for transporting chemicals.

Gas Processing

Gas processing facilities utilize body flanges to connect various components within their systems.

Specialty Chemicals

In the production of specialty chemicals, body flanges play a vital role in maintaining the integrity of the process.

Image source: Texas Flange

Frequently Asked Questions (FAQs)

What is the role of Body Flanges in industries?

Body flanges play a critical role in connecting pipes, valves, and equipment in various industries. They ensure secure, leak-free connections, even under high-pressure and high-temperature conditions.

Why are there different types of Body Flanges?

Different types of body flanges are designed to meet specific needs. For example, Weld Neck Flanges are used in high-pressure applications, while Slip On Flanges provide simplicity.

How do Blind Flanges contribute to industrial processes?

Blind Flanges cap off pipes and lines, providing a seal. They can also be customized to include specific features, making them versatile components.

In what situations are Socket Weld / Counter Bore Flanges preferred?

Socket Weld / Counter Bore Flanges are used in confined spaces where standard Weld Neck flanges may not fit comfortably.

What is the significance of Threaded / Companion Flanges?

Threaded / Companion Flanges are essential for reducing connections with threaded centers, allowing for easy assembly and disassembly.

Why are Lap Joint Flanges used over stub end fittings?

Lap Joint Flanges are designed to fit over stub end fittings and offer flexibility in joint configurations.

Which materials are commonly used for Body Flanges?

Materials include stainless steel, alloy steel, carbon steel, nickel alloys, and copper alloys, chosen based on factors like corrosion resistance and temperature tolerance.

How do Body Flanges enhance the efficiency of heat exchangers?

Body flanges maintain secure connections in heat exchangers, ensuring efficient heat transfer between fluids.

What industries rely on Body Flanges for their operations?

Industries such as pharmaceuticals, chemicals, power generation, petrochemicals, and offshore oil drilling utilize body flanges for their piping systems.

What is the significance of understanding Body Flanges in modern engineering?

Understanding body flanges is crucial to appreciating their role in creating reliable and efficient industrial processes, contributing to the functioning of our modern world.

Conclusion

In conclusion, body flanges have an important role from the industrial point of view, ensuring that pipes and equipment work seamlessly together. They come in different types and are made from various materials to suit specific applications. Whether it’s in pharmaceuticals, petrochemicals, or power generation, body flanges are indispensable for creating secure and efficient connections..For more information about the body flange visit TexasFlange.com or https://en.wikipedia.org/wiki/Flange